Understanding the Art of Welding: Exactly How to Prevent Undercut Welding Issues for Flawless Construction Results

Efficiency and accuracy are extremely important worldwide of welding, where even the least blemish can jeopardize the structural integrity of a fabricated item. One typical difficulty that welders face is undercutting, a problem that can compromise a weld joint and lead to expensive rework. By understanding the source of undercut welding and carrying out reliable techniques to avoid it, welders can boost their craft to new degrees of quality (Preventing weld undercut). In the quest of remarkable construction outcomes, understanding the art of welding to prevent undercut concerns is not simply an ability however a requirement for those pursuing excellence in their job.

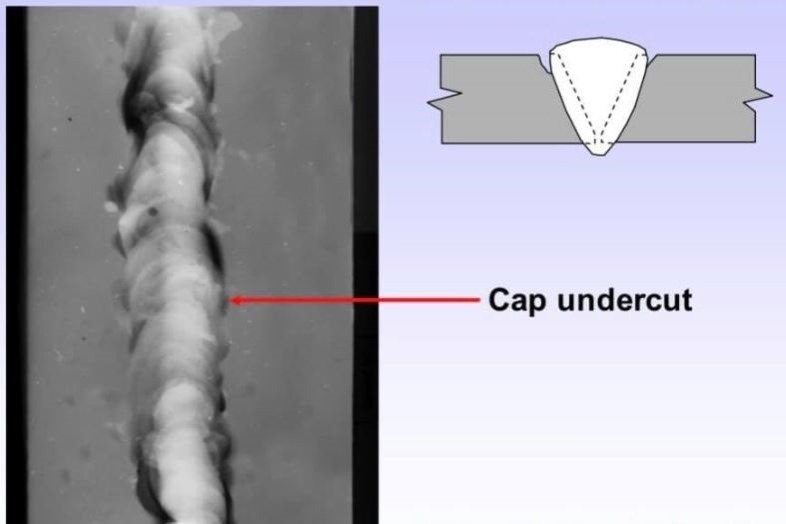

Recognizing Undercut Welding

To protect against undercut welding, welders should guarantee appropriate welding criteria, such as adjusting the present, voltage, traveling rate, and preserving the proper electrode angle. By recognizing the reasons of undercut welding and carrying out precautionary steps, welders can accomplish top notch, structurally audio welds.

Root Causes Of Undercut in Welding

Recognizing the aspects that add to undercut in welding is crucial for welders to generate high-grade, structurally audio welds. When the weld metal does not correctly fill the groove created between the base metal and the formerly deposited weld metal, undercutting occurs. Numerous variables can cause damage in welding. One usual cause is too much warmth input. Welding at heats for extended durations can cause the base steel melting more than desired, resulting in undercut. Inadequate welding incorrect or current welding speed can also add to undercut. Inadequate current may not provide sufficient heat to thaw the base and filler metals adequately, while extreme speed can avoid correct blend, triggering undercut. Furthermore, improper electrode angles or wrong torch control methods can develop areas of low weld steel deposition, advertising undercut. Comprehending these causes and executing appropriate welding techniques can aid prevent undercutting concerns, guaranteeing long lasting and solid welds.

Methods to avoid Undercutting

To reduce the risk of undercutting in welding, welders can use strategic welding strategies aimed at improving the quality and stability of the weld joints. In addition, making use of the proper welding method for the specific joint setup, such as weave or stringer beads, can add to minimizing undercutting.

Additionally, proper joint preparation, consisting of guaranteeing clean base products devoid of contaminants and utilizing the appropriate welding consumables, is crucial in protecting against undercut problems. Utilizing back-step welding methods and controlling the weld bead account can additionally help distribute heat uniformly and decrease the danger of undercut. Routine examination of the weld joint during and after welding, along with applying quality control actions, can assist in resolving and identifying undercutting concerns quickly. By executing these strategies next page faithfully, welders can accomplish flawless fabrication results with minimal undercut problems.

Significance of Correct Welding Criteria

Selecting and keeping appropriate welding criteria is vital for accomplishing effective welds with very little defects. Welding specifications describe variables such as voltage, present, take a trip speed, electrode angle, and shielding gas flow price that straight affect the welding procedure. These parameters have to be carefully changed based on the type of product being welded, its thickness, and the welding strategy employed.

Proper welding parameters ensure the appropriate quantity of warm is put on melt the base steels and filler product evenly. If the parameters are established too high, it can lead to excessive warmth input, creating burn-through, spatter, or distortion. On the various other hand, if the parameters are as well reduced, insufficient fusion, absence of infiltration, or undercutting might happen.

Quality Control in Welding Workflow

Verdict

In final thought, mastering the art of welding calls for an extensive understanding of undercut welding, its causes, and strategies to avoid it. By guaranteeing proper welding criteria and applying quality assurance practices, perfect construction results can be accomplished. It is crucial for welders to constantly strive for excellence in their welding procedures to avoid undercut concerns and generate premium welds.

Undercut welding, a typical flaw in welding procedures, occurs when the weld metal doesn't appropriately fill the groove and leaves a groove or anxiety pop over to these guys along the welded joint.To stop undercut welding, welders must guarantee proper welding parameters, such as readjusting the existing, voltage, travel speed, and preserving the appropriate electrode angle. Poor welding present or incorrect welding speed can additionally add to undercut.To mitigate the risk of damaging in welding, welders can utilize strategic welding methods aimed at improving the top quality and honesty of the weld joints.In conclusion, mastering the art of welding calls for a detailed understanding of undercut welding, its reasons, and click methods to stop it.